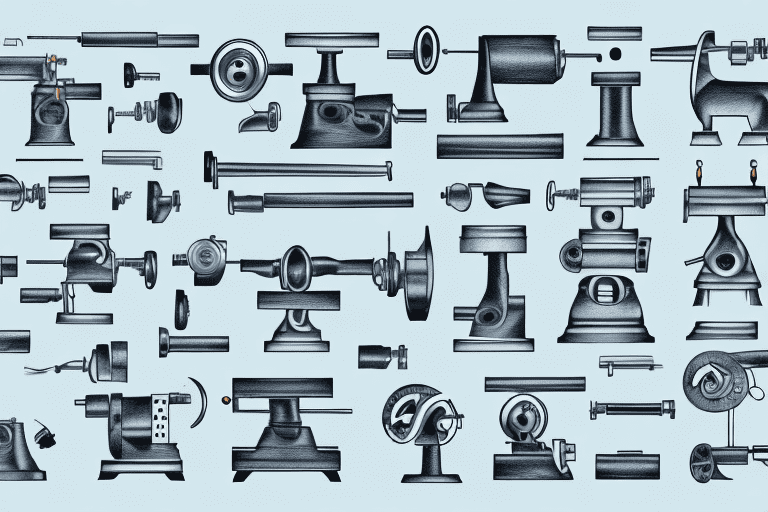

In the world of machining, lathe dogs play a crucial role in securing workpieces to the lathe during turning operations. These mechanical devices, also known as lathe carriers or lathe clamps, come in different types and designs to accommodate various machining tasks and workpiece materials.

Understanding the Basics of Lathe Dogs

Before delving into the specifics of different lathe dog types, it is important to grasp the fundamental concepts behind these indispensable tools. Firstly, what exactly are lathe dogs? Lathe dogs are attachments or clamps that are typically comprised of two main components: the body and the tail. The body is the part that connects to the lathe chuck, while the tail holds the workpiece in place using its jaws or projections.

Lathe dogs are primarily used to transmit rotational force from the lathe spindle to the workpiece, facilitating smooth and precise turning. By securely gripping the workpiece, lathe dogs enable the lathe to cut into the material without causing any slippage or displacement.

Definition and Function of Lathe Dogs

Lathe dogs can be defined as mechanical clamping devices used in machining operations to secure workpieces onto a lathe. Their primary function is to provide a reliable and secure grip on the workpiece, allowing for efficient and accurate turning.

When it comes to the function of lathe dogs, it is important to understand how they work in conjunction with the lathe chuck. The body of the lathe dog is attached to the chuck, which is responsible for holding the workpiece in place. The tail of the lathe dog, on the other hand, holds the workpiece firmly with its jaws or projections. This dual mechanism ensures that the workpiece remains stable and does not move during the turning process.

Moreover, lathe dogs play a crucial role in transmitting rotational force from the lathe spindle to the workpiece. As the lathe spindle rotates, the lathe dog transfers this rotational motion to the workpiece, allowing for the desired turning action to take place. This seamless transfer of force ensures that the cutting tool engages with the workpiece accurately and consistently.

Importance of Lathe Dogs in Machining

The significance of lathe dogs in machining cannot be overstated. Without these vital tools, it would be challenging, if not impossible, to perform various turning operations. Lathe dogs ensure workpiece stability, preventing unwanted movement or slipping during the machining process. This, in turn, guarantees precise cuts and consistent results.

Furthermore, lathe dogs allow machinists to exert control over the workpiece, enabling them to achieve desired shapes, dimensions, and surface finishes. By securely gripping the workpiece, lathe dogs eliminate the risk of inaccuracies and ensure the integrity of the machined part.

In addition to their role in ensuring workpiece stability and control, lathe dogs also contribute to the overall efficiency of the machining process. By securely holding the workpiece, lathe dogs allow for higher cutting speeds and feed rates, resulting in faster and more productive turning operations. This increased efficiency translates into time and cost savings for machinists and manufacturers.

Moreover, lathe dogs are versatile tools that can accommodate a wide range of workpiece sizes and shapes. With adjustable jaws or projections, lathe dogs can adapt to different workpiece diameters and configurations, making them suitable for various machining applications.

Overall, lathe dogs are essential components in the world of machining. Their ability to provide stability, control, and efficiency makes them indispensable tools for turning operations. Whether it is a small hobby lathe or a large industrial lathe, lathe dogs play a vital role in ensuring accurate and precise machining results.

Exploring the Various Types of Lathe Dogs

Now that we have a solid understanding of the role and importance of lathe dogs, let’s take a closer look at the different types available in the market. Each type of lathe dog offers unique features that make them suitable for specific machining tasks.

Bent Tail Lathe Dogs

Bent tail lathe dogs, also known as round-nose lathe dogs, are one of the most common types in use. As the name suggests, these lathe dogs have a curved tail, which provides a secure grip on cylindrical workpieces. The curved design allows for an even distribution of clamping force, minimizing the risk of deformation or damage to the workpiece.

Straight Tail Lathe Dogs

In contrast to the curved tail design of bent tail lathe dogs, straight tail lathe dogs feature a linear tail configuration. These straight-tailed dogs are particularly well-suited for gripping flat or rectangular workpieces securely. Their straight design provides stability and prevents any tilting or wobbling during turning operations.

Clamp Type Lathe Dogs

As the name suggests, clamp-type lathe dogs employ a clamping mechanism to secure the workpiece. This type of lathe dog is versatile and can handle a wide range of workpiece shapes and sizes. The clamping mechanism can be operated manually or using a lever, providing convenience and ease of use.

Carrier or Drive Dogs

Carrier or drive dogs are designed for handling large or heavy workpieces. They feature robust jaws or projections that can firmly grip heavy workpieces and withstand the forces generated during machining. Carrier dogs provide enhanced stability and ensure safe and efficient turning of larger workpieces.

Selecting the Right Lathe Dog for Your Needs

Choosing the appropriate lathe dog for your machining needs is crucial to ensure optimal results. Several factors come into play when making this decision.

Factors to Consider When Choosing a Lathe Dog

When selecting a lathe dog, consider the following factors:

- Workpiece Size and Shape: Different lathe dogs are designed to handle specific workpiece sizes and shapes. Assess the dimensions and configuration of your workpiece to determine which lathe dog will provide the most secure grip.

- Material Compatibility: Consider the type of material you will be machining. Some lathe dogs are better suited for certain materials, such as metals or woods, due to their gripping characteristics.

- Accessibility: Take into account the accessibility of the workpiece and the lathe chuck. Ensure that the chosen lathe dog can be easily attached and removed as needed.

- Application Specifics: Consider the specific machining operations you will be performing. Certain lathe dog types may offer advantages for particular tasks, such as heavy-duty turning or precision work.

Matching Lathe Dog Type to Specific Tasks

Based on the factors mentioned above, it is essential to match the lathe dog type to the specific machining tasks at hand. Bent tail or round-nose lathe dogs are ideal for cylindrical workpieces, while straight tail dogs excel at gripping flat or rectangular materials. Clamp-type lathe dogs offer versatility, while carrier or drive dogs are suitable for heavy-duty applications.

Proper Usage and Maintenance of Lathe Dogs

Now that you have selected the appropriate lathe dog for your needs, it is essential to understand how to use and maintain it effectively.

How to Use Lathe Dogs Safely and Effectively

When using lathe dogs, follow these guidelines to ensure safe and efficient operation:

- Securely attach the lathe dog to the lathe chuck, ensuring a tight and reliable connection.

- Properly position the workpiece within the lathe dog’s jaws or projections, ensuring a secure and stable grip.

- Test the grip by applying gentle pressure before commencing machining operations.

- Regularly monitor the lathe dog during turning to ensure that the workpiece remains securely clamped.

Tips for Maintaining Your Lathe Dogs

To prolong the lifespan and maximize the performance of your lathe dogs, consider the following maintenance tips:

- Regularly clean and lubricate the lathe dog to prevent debris buildup and ensure smooth operation.

- Inspect the jaws or projections for wear or damage and replace them if necessary.

- Store lathe dogs in a clean and dry environment to prevent rust or corrosion.

- Periodically check the alignment and condition of the lathe chuck to ensure compatibility with the lathe dog.

Troubleshooting Common Issues with Lathe Dogs

Despite their reliability and efficiency, lathe dogs can encounter certain issues that may affect their performance. It is essential to identify and address these issues promptly to avoid any negative impact on machining outcomes.

Identifying and Resolving Lathe Dog Problems

Common issues with lathe dogs and their possible solutions include:

- Slippage: If the lathe dog is slipping during machining, check that the workpiece is properly secured within the jaws or projections. Ensure that the lathe dog is attached securely to the lathe chuck.

- Deformation: If the workpiece is experiencing deformation due to clamping pressure, consider using a lathe dog with a different tail design or distribute the clamping force more evenly.

- Wear and Tear: Inspect the lathe dog regularly for signs of wear or damage, such as worn-out jaws or projections. Replace any worn components to maintain optimal performance.

Preventing Common Lathe Dog Issues

To minimize the occurrence of common lathe dog issues, follow these preventive measures:

- Ensure that the lathe dog is compatible with the workpiece material and dimensions.

- Avoid excessive clamping force that may lead to workpiece deformation.

- Maintain regular cleaning and lubrication to prevent debris buildup.

- Inspect the lathe dog and its components regularly for signs of wear or damage.

By understanding the different types of lathe dogs, their functions, and how to use and maintain them effectively, machinists can harness the full potential of these indispensable tools. Whether turning cylindrical, flat, or heavy workpieces, selecting the right lathe dog and employing proper techniques will ensure optimal machining results and enhance overall productivity.

Turn Your Real Dog into a Work of Art

While you’ve mastered the art of machining with the right lathe dog, why not turn your attention to another kind of dog—your beloved pet? With My Good Doggo, you can transform your dog’s photo into a whimsical masterpiece using AI. Just as you select the perfect lathe dog for your projects, choose from a variety of artistic styles to capture your furry friend’s personality in a unique and creative way. Ready to see your dog in a new light? Use the My Good Doggo App today and easily share your pet’s artistic avatar with the world!