Ratchet type dog clutches are an essential component in many mechanical systems, providing numerous advantages over other types of clutches. Understanding the functioning and key components of these clutches is crucial to recognizing their benefits and potential applications.

Understanding Ratchet Type Dog Clutches

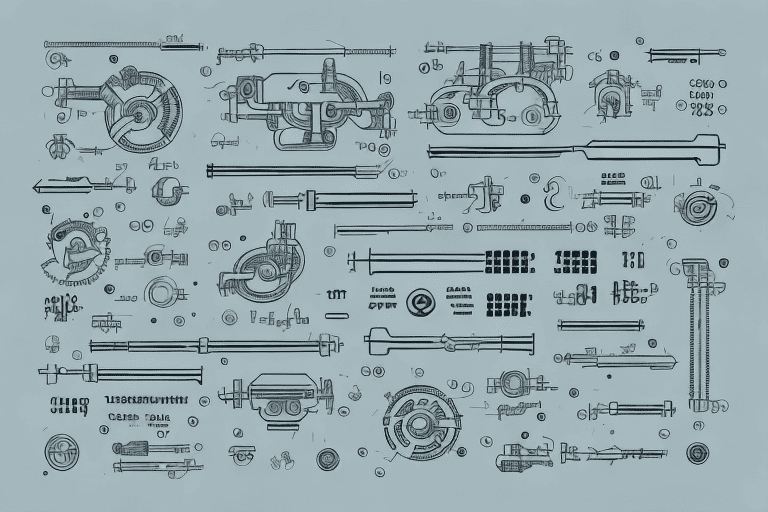

Ratchet type dog clutches are mechanical devices commonly used to transmit torque and rotation between two shafts. They consist of two main components: the driving member and the driven member. The driving member, typically attached to the input shaft, rotates and engages with the driven member, connected to the output shaft.

The basic functioning of ratchet type dog clutches involves the interlocking of dog teeth on the driving and driven members. These teeth, arranged in a circular pattern, enable smooth engagement and disengagement of the clutch. When the driving member rotates, the dog teeth on both members align, allowing torque to be transferred to the driven member. When disengaged, the dog teeth separate, halting torque transmission.

Basic Functioning of Ratchet Type Dog Clutches

One of the key advantages of ratchet type dog clutches lies in their simple and reliable functioning. The dog teeth mechanism ensures precise engagement and disengagement, minimizing the chances of slippage or sudden disconnection. This stable and consistent operation enhances the overall efficiency and performance of mechanical systems.

Furthermore, ratchet type dog clutches are designed to handle high torque loads, making them suitable for various applications, such as power transmission in heavy machinery, automotive systems, and industrial equipment. The robust construction of these clutches ensures durability and long service life, even under demanding operating conditions.

Moreover, ratchet type dog clutches offer versatility in terms of speed and direction control. By adjusting the engagement mechanism, the clutch can be configured to provide different speed ratios or reverse rotation, allowing for greater flexibility in system design and operation.

Key Components of Ratchet Type Dog Clutches

In addition to the dog teeth, ratchet type dog clutches consist of several other essential components. These include the actuating mechanism, which controls the engagement and disengagement of the clutch, and the guide pins, which guide the driving member into proper alignment with the driven member. Proper maintenance and lubrication of these components are crucial for optimal performance and longevity of the clutch system.

The actuating mechanism can vary depending on the specific application and design requirements. It may involve a lever, cam, or hydraulic system that applies force to engage or disengage the clutch. The guide pins, on the other hand, ensure precise alignment of the driving and driven members, preventing misalignment and potential damage to the clutch.

Additionally, ratchet type dog clutches may incorporate features such as overload protection mechanisms or adjustable torque settings to enhance their functionality and safety. These features allow the clutch to disengage automatically when the torque exceeds a certain threshold, protecting the system from damage and preventing excessive wear on the clutch components.

In conclusion, ratchet type dog clutches are reliable and efficient devices used for torque transmission in various mechanical systems. Their simple yet robust design, along with the interlocking dog teeth mechanism, ensures precise engagement and disengagement, making them suitable for demanding applications. By understanding the basic functioning and key components of these clutches, engineers and technicians can effectively utilize them in their designs and maintain their optimal performance over time.

Advantages of Using Ratchet Type Dog Clutches

Ratchet type dog clutches offer several advantages that make them a preferred choice in various mechanical systems. These advantages range from enhanced durability and longevity to improved efficiency in power transmission.

Enhanced Durability and Longevity

One of the primary advantages of ratchet type dog clutches is their excellent durability and longevity. The engagement and disengagement mechanism of the dog teeth ensures smooth and precise operation, reducing wear and tear on the clutch components. This longevity translates into reduced maintenance and replacement costs, making ratchet type dog clutches a cost-effective solution for many applications.

Moreover, the materials used in manufacturing ratchet type dog clutches are carefully selected to withstand high levels of stress and friction. This ensures that the clutches can endure heavy loads and prolonged usage without compromising their performance. Whether it’s in heavy machinery or industrial equipment, ratchet type dog clutches prove to be reliable and long-lasting components.

Improved Efficiency in Power Transmission

Ratchet type dog clutches offer superior efficiency in power transmission, particularly when compared to friction clutches. The direct engagement of the dog teeth provides a more reliable and efficient transfer of torque, minimizing energy loss due to slippage or heat generation. This improved efficiency can significantly enhance the overall performance of mechanical systems, leading to increased productivity and reduced energy consumption.

Furthermore, the precise and positive engagement of the dog teeth ensures that power is transmitted smoothly and without any hiccups. This eliminates the need for constant adjustments or fine-tuning, allowing the system to operate at its optimal level. The improved power transmission efficiency of ratchet type dog clutches makes them ideal for applications where precision and reliability are crucial.

Versatility in Various Mechanical Systems

Ratchet type dog clutches exhibit versatility in their applications, as they can be utilized in a wide range of mechanical systems. From industrial machinery to automotive transmissions, these clutches can successfully handle different torque and rotation requirements. Their adaptability and compatibility with various system configurations make them a valuable component in many industries.

For instance, in the automotive industry, ratchet type dog clutches are commonly used in manual transmissions. They allow for smooth gear shifting and precise engagement, ensuring a seamless driving experience. In industrial machinery, these clutches find applications in conveyor systems, where they enable efficient power transmission and reliable operation.

Additionally, ratchet type dog clutches can be found in agricultural equipment, marine propulsion systems, and even in aerospace applications. Their versatility and ability to handle varying loads and speeds make them a popular choice across different sectors.

Comparison with Other Types of Clutches

When considering clutch options for a specific application, it is essential to compare ratchet type dog clutches with other available types. By examining their differences and advantages, one can make an informed decision regarding the most suitable clutch for their mechanical system.

Ratchet Type Dog Clutches vs. Friction Clutches

Compared to friction clutches, ratchet type dog clutches offer more reliable and efficient torque transmission. Friction clutches rely on frictional forces, which can result in slippage and reduced power transfer. Ratchet type dog clutches, on the other hand, provide direct engagement, minimizing the chances of power loss. Additionally, the wear and tear associated with friction clutches are significantly reduced in ratchet type dog clutches, contributing to their extended lifespan.

Ratchet Type Dog Clutches vs. Hydraulic Clutches

Hydraulic clutches operate using hydraulic fluid pressure to engage and disengage the clutch. Although hydraulic clutches can offer smooth and precise operation, they require additional components such as pumps and reservoirs, increasing overall system complexity and maintenance requirements. Ratchet type dog clutches, in contrast, offer a simpler and more compact solution without the need for hydraulic systems.

Maintenance and Care for Ratchet Type Dog Clutches

To ensure optimal performance and longevity of ratchet type dog clutches, proper maintenance and care are essential. Regular inspection and maintenance can help identify potential issues and prevent costly breakdowns.

Routine Inspection and Maintenance Tips

Periodically inspecting the clutch components for wear, misalignment, or damage is crucial. Lubrication of the dog teeth, guide pins, and other moving parts should be performed as recommended by the manufacturer. Additionally, following proper installation practices and keeping the clutch system clean can contribute to its longevity and reliable operation.

Common Issues and Troubleshooting

Some common issues that may arise with ratchet type dog clutches include excessive wear of dog teeth, misalignment, or inadequate lubrication. If any of these issues are detected, immediate corrective action should be taken to avoid further damage and ensure the proper functioning of the clutch. Consulting the manufacturer’s guidelines or seeking professional assistance can aid in troubleshooting and resolving these issues effectively.

Future Developments in Ratchet Type Dog Clutches

The field of clutch technology is continuously evolving, and ratchet type dog clutches are no exception. Technological advances and developments in material science are driving innovations in clutch design, further enhancing their performance and versatility.

Technological Advances and Innovations

Advancements in materials and manufacturing techniques are enabling the production of ratchet type dog clutches with improved strength and durability. The use of advanced alloys and surface treatments can enhance the resistance to wear and fatigue, prolonging the clutch’s lifespan even further. Additionally, innovations in actuating mechanisms and control systems are leading to more precise and responsive clutch engagement, enhancing overall system performance.

Impact of Material Science on Clutch Design

Material science plays a vital role in the development of ratchet type dog clutches. The selection of suitable materials for the dog teeth, guide pins, and other components can significantly impact their performance and reliability. Ongoing research and developments in material science are expected to result in innovative clutch designs that offer superior strength, reduced weight, and enhanced resistance to harsh operating conditions.

Conclusion

Ratchet type dog clutches provide significant advantages in mechanical systems, including enhanced durability, improved efficiency, and versatile applications. By understanding their functioning, key components, and maintenance requirements, engineers and system designers can make informed decisions regarding the use of ratchet type dog clutches. Moreover, ongoing advancements in clutch technology and material science continue to expand the capabilities and potential of these clutches, ensuring their relevance in future mechanical systems.

Unleash Your Dog’s Artistic Side with My Good Doggo

Just as ratchet type dog clutches are integral to the smooth operation of mechanical systems, capturing the essence of your beloved pet is key to cherishing those special moments. With My Good Doggo, you can immortalize your dog’s personality in a unique and artistic way. Transform your furry friend’s photo into a stunning piece of AI-generated art and share the masterpiece with the world. Ready to see your dog in a new light? Use the My Good Doggo App today and let the creativity flow!